ANNOUNCEMENT FROM GPI

Due to supply chain difficulties and rapidly increasing costs of materials, GPI has decided to discontinue making our RIMS® and Dynamount™ products. What we have left in stock is available on the Order page for each product. Any sizes out of stock will no longer be available. In certain cases we may have "factory seconds/slightly blemished" sizes available, in which case we will offer them for sale for a small discount in a separate section below. Thank you to everyone who has supported RIMS® and Dynamount™ over the years. Please note that we will continue to sell our other products available on this website.

Due to supply chain difficulties and rapidly increasing costs of materials, GPI has decided to discontinue making our RIMS® and Dynamount™ products. What we have left in stock is available on the Order page for each product. Any sizes out of stock will no longer be available. In certain cases we may have "factory seconds/slightly blemished" sizes available, in which case we will offer them for sale for a small discount in a separate section below. Thank you to everyone who has supported RIMS® and Dynamount™ over the years. Please note that we will continue to sell our other products available on this website.

"I got the Dynamount™ and installed it yesterday. What a difference!!

HUGE increase in the resonance & sustain. It works beautifully."

-Kevin Hayes, Robert Cray Band

In A Drum Shell:

Floor tom resonance is truly at the mercy of how it is mounted and the surface the drum is sitting on. It can easily be choked by the heavy brackets and legs that are attached to the drum's shell. The Dynamount™ works by removing all mounting hardware from the shell of the drum. This allows the resonance to stay with the drum and not be transferred into the mounting hardware, legs, floor, or nearby stands your legs happen to contact. If you want to test your drum for resonance loss, compare the drum's sound when lifted off the floor and when set back down. Also, grab the floor tom legs as you strike the drum to feel how much vibration/resonance is transferring to the legs. To take it a step further, remove the legs and mounting hardware from the shell and strike the drum while it is held in the air. The results of these tests may surprise you. The stress free mounting is what the Dynamount™ is designed to achieve.

Floor tom resonance is truly at the mercy of how it is mounted and the surface the drum is sitting on. It can easily be choked by the heavy brackets and legs that are attached to the drum's shell. The Dynamount™ works by removing all mounting hardware from the shell of the drum. This allows the resonance to stay with the drum and not be transferred into the mounting hardware, legs, floor, or nearby stands your legs happen to contact. If you want to test your drum for resonance loss, compare the drum's sound when lifted off the floor and when set back down. Also, grab the floor tom legs as you strike the drum to feel how much vibration/resonance is transferring to the legs. To take it a step further, remove the legs and mounting hardware from the shell and strike the drum while it is held in the air. The results of these tests may surprise you. The stress free mounting is what the Dynamount™ is designed to achieve.

Specifics:

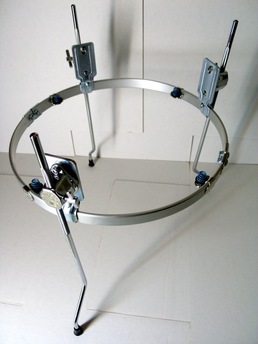

Instead of mounting heavy hardware to the shell of a drum, the Dynamount™ uses 4 evenly distributed spring grommets to work as isolating supports for the drum's bottom lugs. We also use different springs to support/isolate different drum's sizes/weights. A softer blue spring for 12", 13", and 14" floor toms, and a firmer red spring for 15",16", and 18" floor toms. The RIMS® Adjustable Flange is used so the springs can be aligned perfectly to the lugs. The end connectors that join the two bands together are also designed for custom adjustability, permitting adjustment of the aluminum bands for a perfect fit.

Instead of mounting heavy hardware to the shell of a drum, the Dynamount™ uses 4 evenly distributed spring grommets to work as isolating supports for the drum's bottom lugs. We also use different springs to support/isolate different drum's sizes/weights. A softer blue spring for 12", 13", and 14" floor toms, and a firmer red spring for 15",16", and 18" floor toms. The RIMS® Adjustable Flange is used so the springs can be aligned perfectly to the lugs. The end connectors that join the two bands together are also designed for custom adjustability, permitting adjustment of the aluminum bands for a perfect fit.

PLEASE NOTE:

The Dynamount™ comes with everything you see pictured here. It DOES NOT come with legs or leg mounting hardware, as most people who buy the Dynamount™ already have these items. Basic legs and leg mounting hardware can be purchased at the bottom of the Dynamount™ order page. We highly recommend using the video instructions below as a step by step guide for properly installing the Dynamount™.

The Dynamount™ comes with everything you see pictured here. It DOES NOT come with legs or leg mounting hardware, as most people who buy the Dynamount™ already have these items. Basic legs and leg mounting hardware can be purchased at the bottom of the Dynamount™ order page. We highly recommend using the video instructions below as a step by step guide for properly installing the Dynamount™.

|

Also please be aware that the finish on the Dynamount™ is now done differently than on our regular RIMS® mounts. If you are using both on your kit, they won't be a perfect match. The Dynamount™ System is powder coated, while RIMS® are anodized. The anodizing process has become very expensive over the years, and it has just not remained realistic to continue using it for all of the parts of the Dynamount™. We have done our best to get them as close as possible to one another. The picture on the right shows the difference between the two. On the left is an anodized RIMS® band, and on the right is a powder coated Dynamount™ band.

|